Since 1980, AudioQuest, headquartered in Irvine, California, has been a leading developer, manufacturer, and distributor of high-performance audio/video products and custom-install solutions. Although best known for our comprehensive range of analog, digital, and AC power cables, our portfolio has expanded to a diverse assortment of products, including the multi award-winning DragonFly DACs, Niagara and PowerQuest power products.

Our ultimate goal is the same today as was from the start: Do No Harm! By this we mean that all cables and components, to the extent that is technologically feasible, should get out of the music’s way by inducing the least amount of noise and distortion.

The Evolution Continues: The Four Elements Today

While minimizing noise and damage to the audio signal remains the North-Star constant, the ways in which AudioQuest engages these challenges always evolves. While there are still Four Elements that describe our foundational materials and design philosophies, a growing number of technologies cross and even go beyond our original Four Elements. Many have become crucial enough to demand visibility. Noise-Dissipation is an umbrella Element under which many of these meaningful techniques and technologies will reside. While Geometry is no longer identified as one of The Four Elements, it remains inextricably tied to all other Elements of cable design and manufacture.

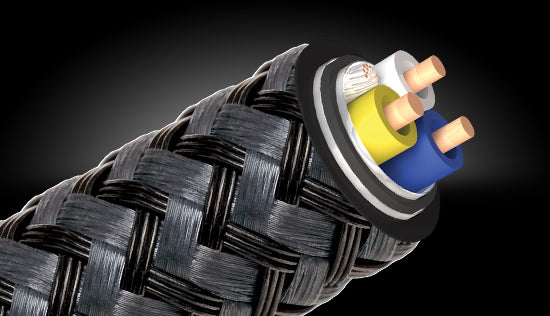

Solid Conductors

Strand interaction remains the biggest potential source of distortion in cables. Solid Conductors are the aspirational ideal and most complete solution to this problem. However, thoughtfully arranged multi-conductor geometries such as concentric windings are used to create our Semi-Solid Conductor technologies. These avoid many strand-distortion mechanisms and are in their own right ideal in a growing number of applications.

Directionality

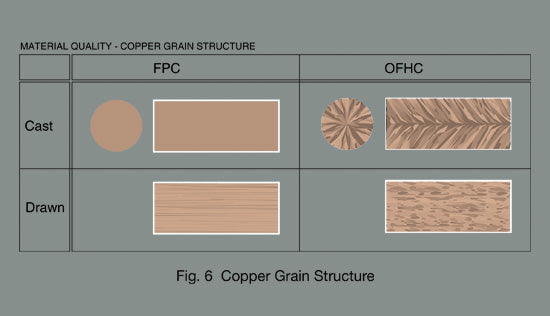

All drawn metal conductors have a non-symmetrical, fish-scale-like grain structure. Because the highest Radio Frequencies (RF) are subject to skin effect, traveling on this deformed outer-surface layer of the conductor, there is a resulting increase in RF impedance in one direction versus the other. Since induced RF noise is parasitic (and doesn’t travel with the primary signal current), it takes the path of least resistance. At AudioQuest, we test every conductor so it is used in the direction that drains the induced noise away from where it will cause the most harm, optimizing the cable and the system’s performance.

Noise-Dissipation

Unwanted Radio-Frequency (RF) noise is and has always been picked up and induced into cable. This contamination ultimately masks and distorts critical portions of the audio/video signal. As this distortion-causing (parasitic) RF signal is more present today than at any previous time in history, we must depend on a wider arsenal of Noise-Dissipation technologies:

- ZERO-Tech (No Characteristic Impedance) applies Ultra-Linear Noise- Dissipation across the widest range of frequencies possible. It also enables uncompressed transient current transfer for AC power and loudspeaker/power amplifier applications.

- RF/ND-Tech (Patented Radio-Frequency Ground-Noise Dissipation) minimizes circuit misbehavior by cancelling induced RF noise.

- Tried-and-true DBS (Dielectric-Bias System) has evolved to include RF-Noise Traps that further reduce dielectric distortion and induced noise.

Metal Quality

Higher-purity conductor metals with smoother surfaces and internal crystal structures greatly reduce noise and distortion. Carefully finessed mixes of metals and conductor sizes can be effectively used to define a cable’s Sonic Signature—a cost-effective technique for high-value, high-performance models.